Tuesday, October 02, 2012

Hello,

Once a fair is over, we normally have different jobs to perform among which is showing the machines we exhibited to those who couldn’t attend the fair.

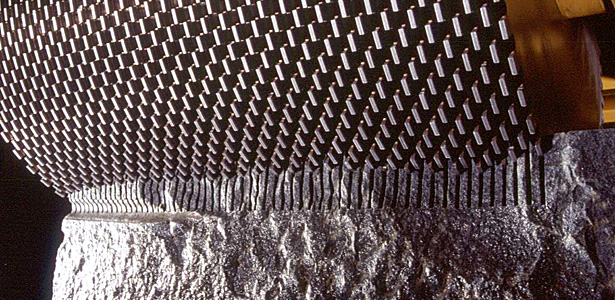

This year, Breton exhibited the new GOLDBRETON 2000/6/V70, a multi-wire machine with 70 wires that achieved resounding success among visitors, especially thanks to its technological features.

Breton history was written by two machines, whose latest version was exhibited in the Pavillion 5 - Stand C5:

Breton history was written by two machines, whose latest version was exhibited in the Pavillion 5 - Stand C5:

- Levibreton KFM, a polisher for marble strip polishing lines

- and the newly coloured Levibreton KG 4000 PLUS, a polisher for granite slab polishing lines that was previewed last year.

Write to mail@breton.it for more info

By-by

Sergio Prior