Hello,

Today I’d like to talk about granite polishing.

I visited the factory of CERESER MARMI in Rivoli Veronese a few days ago.

Mr. Domenico Cereser took over the company management after his father Gianluigi, the founder. CERESER MARMI, established in 1965, is specialized in the processing of marble and granite slabs.

Here Breton installed a line “Levibreton KG 4000 PLUS” for granite slab polishing, which mainly consists of:

1 – Slab automatic loader mod. JOT

The thickness of the slab feeding the polishing machine is sensed by a special laser detector that checks if it conforms to the expected thickness; if not, the slab is excluded and it is calibrated outside the line (if its thickness is higher) or rejected (if its thickness is lower).

The thickness of the slab feeding the polishing machine is sensed by a special laser detector that checks if it conforms to the expected thickness; if not, the slab is excluded and it is calibrated outside the line (if its thickness is higher) or rejected (if its thickness is lower).

Whenever the slab does not fall within the pre-set parameters, an audible and visual alarm turns on at the end of the line so as to forewarn the operator who can handle the material unloading accordingly.

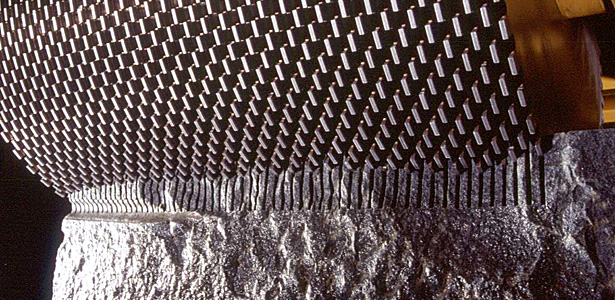

3 - Slab polishing machine Levibreton KG4000PLUS/19

4 - Slab waxing machine with 4 spindles mod. CG/200/4

TYPE OF MATERIAL: natural granite, reinforced with net+resin.

We will install very soon IMAGEPLUS, a Breton system to take, file and code extra high resolution photos of natural and engineered stone slabs, and label the slabs as well.

Therefore, within a few minutes, your own archive with true colour, extra high resolution photos of all the stored slabs will be available.

We will also install APP 22/35, an automatic unit placed before the slab automatic offloader, at the end of the polishing line, which is used to apply points or streaks of thermoplastic polymer on the slab polished face. The function of the points/streaks of polymer (whose number, pitch and shape can be pre-set at will) is to protect the polished face of slabs whenever they are stored and handled arranged in a stack.

Well, that’s all for today.

By-by

Sergio Prior

Today I’d like to talk about granite polishing.

I visited the factory of CERESER MARMI in Rivoli Veronese a few days ago.

Mr. Domenico Cereser took over the company management after his father Gianluigi, the founder. CERESER MARMI, established in 1965, is specialized in the processing of marble and granite slabs.

Here Breton installed a line “Levibreton KG 4000 PLUS” for granite slab polishing, which mainly consists of:

1 – Slab automatic loader mod. JOT

2 - Laser detector of the slab thickness

The thickness of the slab feeding the polishing machine is sensed by a special laser detector that checks if it conforms to the expected thickness; if not, the slab is excluded and it is calibrated outside the line (if its thickness is higher) or rejected (if its thickness is lower).

The thickness of the slab feeding the polishing machine is sensed by a special laser detector that checks if it conforms to the expected thickness; if not, the slab is excluded and it is calibrated outside the line (if its thickness is higher) or rejected (if its thickness is lower).Whenever the slab does not fall within the pre-set parameters, an audible and visual alarm turns on at the end of the line so as to forewarn the operator who can handle the material unloading accordingly.

3 - Slab polishing machine Levibreton KG4000PLUS/19

5 - Unit for the application of a polyester film mod. APLE 20/35

6 - Slab automatic offloader mod. JOT

6 - Slab automatic offloader mod. JOT

6 - Slab automatic offloader mod. JOT

6 - Slab automatic offloader mod. JOT

TYPE OF MATERIAL: natural granite, reinforced with net+resin.

We will install very soon IMAGEPLUS, a Breton system to take, file and code extra high resolution photos of natural and engineered stone slabs, and label the slabs as well.

Therefore, within a few minutes, your own archive with true colour, extra high resolution photos of all the stored slabs will be available.

We will also install APP 22/35, an automatic unit placed before the slab automatic offloader, at the end of the polishing line, which is used to apply points or streaks of thermoplastic polymer on the slab polished face. The function of the points/streaks of polymer (whose number, pitch and shape can be pre-set at will) is to protect the polished face of slabs whenever they are stored and handled arranged in a stack.

Well, that’s all for today.

By-by

Sergio Prior