The Levibreton EUREKA is designed to incorporate a series of MIRAGE heads and SG8 oscillating brick heads..

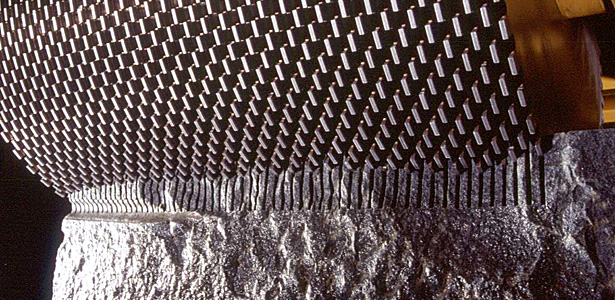

The MIRAGE head is equipped with 6 inclined axis tapered diamond tools offering exceptionally high removal rates. The head rotates at low speed (240 rpm), while the diamond discs spin at 2,800 rpm, allowing the tools to reach a peripheral velocity of 30 m/s: the optimal speed for granite machining.

The MIRAGE head is equipped with 6 inclined axis tapered diamond tools offering exceptionally high removal rates. The head rotates at low speed (240 rpm), while the diamond discs spin at 2,800 rpm, allowing the tools to reach a peripheral velocity of 30 m/s: the optimal speed for granite machining.

Establishing the machining position and operating the MIRAGE heads at their maximum material removal rate, Levibreton EUREKA calibrates slabs to the required thickness.

Calibrating functions aside, the MIRAGE heads work also as polishing heads and the downstream SG8 oscillating heads complete the levelling and polishing operations.

Levibreton EUREKA CUTS THE SCRAP... one machine to perform completely independent machining operations:

- LEVELLING,

- POLISHING.

For info and price of Levibreton EUREKA write to mail@breton.it.

We’ll get back to you promptly.

Well, that’s all for today, thanks for your attention.

Bye-bye

Sergio Prior

We’ll get back to you promptly.

Well, that’s all for today, thanks for your attention.

Bye-bye

Sergio Prior