The history of Savoia Marmi began 40 years ago.

Initially thought as a sawmill hired from local companies (near Verona), nowadays Savoia Marmi is a landmark company in the processing of marble, granite, porphyry and onyx, that can count on lots of prestigious works commissioned worldwide.

The proverbial quality of Savoia Marmi, is the result of thoughtful investments that led the company from a "simple" workshop to a proper natural stone working center: in this way, the company could fit in with an even more frenzied market, though maintaining its know-how.

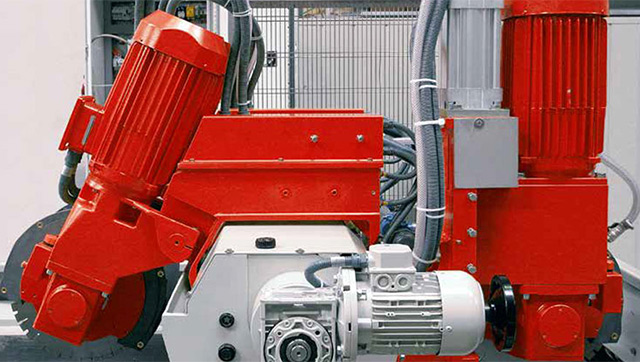

In June 2017, the high-tech stone machinery range of Savoia Marmi was extended thanks to the purchase of a Fuego Multiaxis, a perfect representation of what Breton brand means.

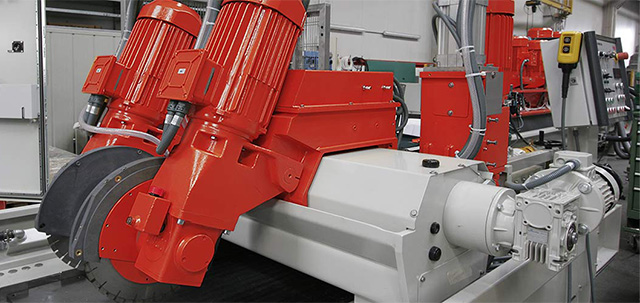

Fuego Multiaxis

is the ideal machine to realize cylindrical/conical columns, column

shells and other complex items that were not available until now.

Our

machine is characterized by the overall dimension of the realizable

pieces and by the technology used to build it: 30 years of Breton experience summed up in the realization of a revolutionary machine.

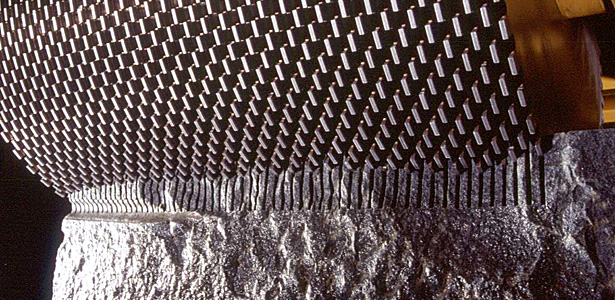

The technical solutions adopted for Breton Fuego Multiaxis made it possible to fix the main issue of this type of machine: the inclination of the diamond wire.

To obtain wide cutting angles, the machine should operate under the ground level. Breton has been able to fix this problem by mounting a cart with two Ø 1000 mm pulleys on every column of the Fuego and letting the two carts move independently.

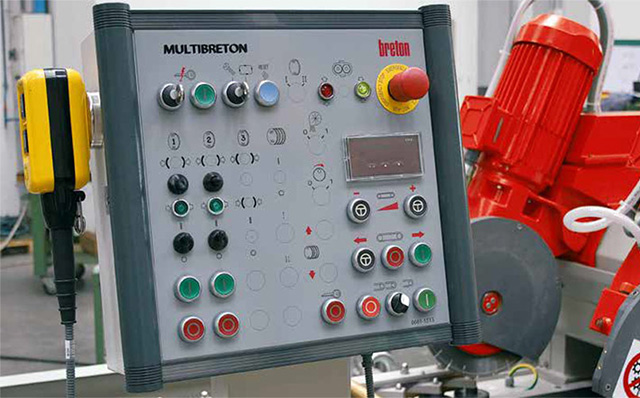

Breton Fuego Multiaxis deals with 4-axis operations with great ease and precision thanks to its 8 interpolated axes, which can be integrated by 2 more axes with motorized positioning.

A simple and performing machine: these are Fuego main features, and the reason why it has been chosen by our prestigious costumer Savoia Marmi.

Breton Fuego Multiaxis deals with 4-axis operations with great ease and precision thanks to its 8 interpolated axes, which can be integrated by 2 more axes with motorized positioning.

A simple and performing machine: these are Fuego main features, and the reason why it has been chosen by our prestigious costumer Savoia Marmi.

|

| Manufactured by the Kienesberger Steinmetz’s Fuego |

No more tanks aside the columns: this system, conceived by Breton, allows Fuego to work with a +/- 20° inclined wire and to process blocks with maximum height of 1800 mm; while, in case of a wire which is parallel to the block supporting platform, Fuego can process blocks as high as 2200 mm.

For more information and prices, on the Breton Fuego Multiaxis, contact mail@breton.it. We’ll get back to you promptly.

Thank you for the attention and best regards.

Bye-bye

Sergio Prior

Bye-bye

Sergio Prior