Today the digital revolution is Breton IMAGE PLUS

(If you click on slabs photo you can see it on full screen)

The way slabs are stored is a common problem faced by the owners of marble and/or granite slab polishing lines each time they want to show their slabs to potential buyers, which in fact involves the following:

- the slab support A-frames take up a lot of room,

- the slab support A-frames take up a lot of room,- an effective system for identifying the slabs is required,

- the overhead crane operator must take out from the slab pile the specific slab to be shown to the customer

- lastly, the slab needs to be correctly placed again in the pile.

It was only with the introduction of Breton IMAGE PLUS (a system to acquire extra-high resolution photos of natural and compound stone slabs and to file, code and label them) that this way of operating has been radically redefined.

It will take just a few minutes to have an image file showing all your stored slabs, with extra-high resolution and true colours!

It will take just a few minutes to have an image file showing all your stored slabs, with extra-high resolution and true colours!

What is Breton IMAGE PLUS?

Breton IMAGEPLUS features an advanced image digitizing technology using a high resolution industrial linear camera and a LED lighting system, which are both specially designed to render the real colours of the material.

Breton IMAGEPLUS features an advanced image digitizing technology using a high resolution industrial linear camera and a LED lighting system, which are both specially designed to render the real colours of the material.

The system sets up automatically according to the slab thickness and makes photos which are not affected by the lighting conditions in the surroundings.

The supply includes a control console complete with PC for photo display and coding; the system links some general information (material, colour, thickness, real and "commercial" dimensions that are set according to user-definable parameters, etc.) to each single photo. Information is stored inside a Microsoft-SQL database which is loaded in a server (not included in the supply).

P.S. The quality of the photos displayed on the PC video depends on the quality and "colour setting" of the video.

P.S. The quality of the photos displayed on the PC video depends on the quality and "colour setting" of the video.

LABELLING

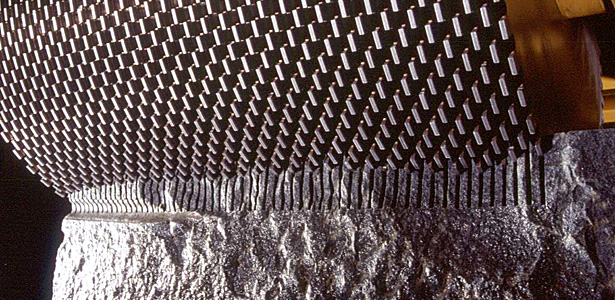

LABELLINGBreton IMAGEPLUS includes a printer of labels with bar code that are manually stuck to the slab surface by the operator (manual labelling).

In the automatic version, the label printer sticks automatically the labels to the slab surface

For request and INFO write to mail@breton.it.

If you wish to receive a free CD with high resolution photos of slabs write to to mail@breton.it.

By-by

Sergio Prior