Paragon is the new multiwire machine entirely designed and built in Breton and is the result of all the experience and know how acquired after installing over 200 Breton/Bidese multiwire machines all over the world. In the multiwire sector, our Paragon has become a “model of excellence”.

Paragon's key features

Isosceles triangular wire geometry with just five transmission (drums/pulleys), the minimum number compatible with the necessary presence of the wire driving drums.

- All the drums, including the wire stretching pulleys, have a diameter of 1.000 mm.

- Adjustable wire driving drums with motor-driven movement so as to be always close to the block.

.jpg)

- All the drums, including the wire stretching pulleys, have a diameter of 1.000 mm.

- Adjustable wire driving drums with motor-driven movement so as to be always close to the block.

.jpg)

Designed to maximize the operator ergonomic comfort:

• Easy access to the machine with practical staircases and gangways

• Fast and easy wire change and positioning

• Immediate and intuitive operator interface of the touch screen for machine management.

• Easy access to the machine with practical staircases and gangways

• Fast and easy wire change and positioning

• Immediate and intuitive operator interface of the touch screen for machine management.

Drums

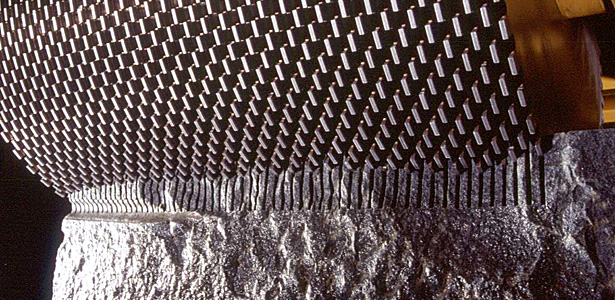

The five rotating drums of Paragon, all of which have a diameter of 1,000 mm, guarantee minimum wire fatigue.

The rigidity of the structure and the isosceles triangular geometry with wires just 20 metres long guarantees lower wire vibrations while cutting, leading to higher cutting quality and longer service life of the rubber profiles.

The rigidity of the structure and the isosceles triangular geometry with wires just 20 metres long guarantees lower wire vibrations while cutting, leading to higher cutting quality and longer service life of the rubber profiles.

The load-bearing structure

The drums and pulleys are installed inside a rigid, boxed steel structure, which runs along the load-bearing columns, stiffly anchored to the ground and stabilized with steel tie rods that ensure a next-to-nothing deformation for the cutting purposes.

This constructive

architecture means we can use columns with a section of 700 x 700 mm,

which offer the same structural stability as columns with a section of

1.300 x 1.300 mm without steel tie rods.

Column deformation while cutting has been checked using finite element mathematical calculations.

Wire stretching pulleys

The wire stretching pulleys, one for each wire and rotating on bearings, are individually driven by a single hydraulic piston ensuring a uniform and constant tension of each wire.

The wire stretching pulleys, one for each wire and rotating on bearings, are individually driven by a single hydraulic piston ensuring a uniform and constant tension of each wire.

The arc of movement of the wire stretching pulleys is very large, therefore the wire installation is very easy and any complicated pre-stretching system has been eliminated.

Wire driving drums

Breton patented the independent, motorized positioning of the two wire driving drums, available as an option.

Wire driving drums

Breton patented the independent, motorized positioning of the two wire driving drums, available as an option.

Each wire driving drum can get as close to the block as 60 cm, therefore they can be positioned near the block to be cut almost always.

This means that:

- the cutting quality is always the best

- the down feed is always the fastest.

This means that:

- the cutting quality is always the best

- the down feed is always the fastest.

Rubber profiles are two-tone (red and gray) to simplify the installation of the wires. Two profile versions are available to meet the customer's requirements:

- three-groove profile alternated with a single-groove profile, which guarantee a longer service life of the profiles as they have thicker "side walls" and are specifically designed for sawing thicknesses of 20 and 30 mm.

.jpg) A

sequence of at least four slabs 20 mm thick or three slabs 30 mm thick

must be positioned with this particular combination of grooves

A

sequence of at least four slabs 20 mm thick or three slabs 30 mm thick

must be positioned with this particular combination of grooves- three-groove profiles to guarantee the greatest versatility in the thickness cutting sequence.

Operator interface

The large colour touch screen makes programming the machine and controlling the processing phases intuitive and user friendly.

All the work settings and parameters can be controlled and displayed on simple pages with big, clearly visible characters.

The “statistics” section lets you display and extract all the data required to manage sawmill and diamond wires, which feature a wisely structured architecture whether you saw blocks for your own company or for third parties.

Exceptional machine accessibility for operators

Footbridges with wide staircases and gangways make it easy and safe for operators to reach all parts of the machine when installing wires or perform servicing.

The multiwire Breton Paragon for cutting granite blocks are available in different version:Footbridges with wide staircases and gangways make it easy and safe for operators to reach all parts of the machine when installing wires or perform servicing.

- from 17 up to 70 wires

- Max. cutting width from 600 up to 1.890mm

Well, that’s all for today, thanks for your attention. Bye-bye

Bye-byeSergio Prior

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)