Multibreton DXS is an automatic cross cutter designed for cutting granite and marble slabs. It can be fitted with up to 7 indipendent 7.5 kW cutter groups, and as it operates in automatic, operator supervision is not required.

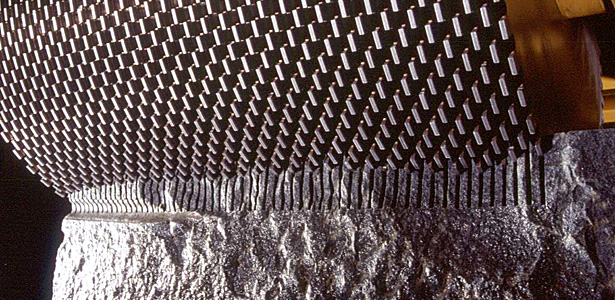

Spindle groups

Each spindle group has a drive power of 7.5 kW and travels on guides enclosed in an oil bath and protected against penetration of water by a labyrinth seal housing and are mounted to a spindle-holder beam configuration. An incorporated pneumatic system raises single spindle groups excluding them from the work cycle . Once the machine has cut the workpiece all the spindle groups are raised preventing the diamond cutting discs from running over the cut slab.

The operator from

the pushbutton control panel activates the servomotors which position

each single spindle group in sequence along the beam. Once the spindle

group has reached its correct working position a hydraulic-lock-system

locks it in position. The operator can control the servomotors from the

display once cutting measurements and disc thickness have been

programmed. Both effective and preset cutting measurements are displayed.

Spindle-holder beam

The spindle-holder beam is amply dimensioned and travels on rolling bearings coupled to toughened steel guides enclosed in an oil bath and protected against penetration of water by a labyrinth seal housing.

Beam travel speed can be adjusted programming slower speeds when the discs approach the workpiece to be cut and start cutting and when they are raised after cutting operations have terminated.

Work Cycle

The Multibreton DXS work cycle is fully automatic and does not require the supervision of an operator:

1 - The slab to cut is positioned on a conveyor which travels on the workbench. The conveyor consists of a multilayer belt with a thick rubber coating ideal for resisting cuts caused by the diamond disc cutters when operating.

2 - The slab automatically stops when it reaches a concealed end stop.

3 - A motorised longitudinal end stop maintains the slab aligned during cutting operations.

4 - Once cutting operations have terminated the discs are raised off the workpiece and then returned to their original position and the slab cut into tiles is discharged from the machine and a new slab is fed in.

3 - A motorised longitudinal end stop maintains the slab aligned during cutting operations.

4 - Once cutting operations have terminated the discs are raised off the workpiece and then returned to their original position and the slab cut into tiles is discharged from the machine and a new slab is fed in.

Water, electric and greasing systems

The systems as water supply to each single spindle group, wiring and electrics are positioned at the rear of the machine for easy and quick access for maintenance or inspection purposes.

Nearly all

machine travel components can be greased from just one easily accessible

point. A sealed housing encloses all machine electric and electronic control and command components.

Programming unit

The machine is PLC controlled. The operator from a simple-to-use keypad provided with display mounted to the machine and located in a safe position and away from humidity, can program and control cutting parameters and settings.

Technical specifications

Now you know all about our Multi-discs cross cutter machine for marble and granite Multibreton DXS.

For info and price write to mail@breton.it.

Thank you for attention. Bye-bye

Sergio Prior