BESTWIRE

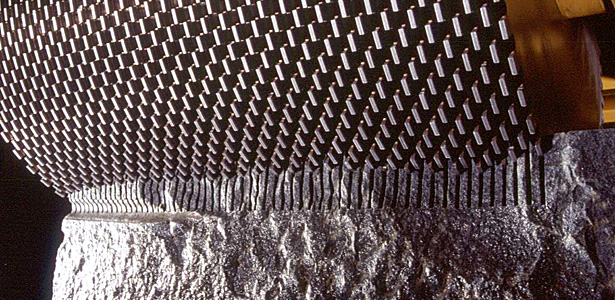

2 AXES SHAPING MACHINE

Machine structure and mechanisms

Machine structure and mechanisms

Heavy-duty, heat treated arc-welded steel structure ensuring the required stiffness of the system and cutting precision of the machine. Two opposite carts containing the components for the wire motion, slide vertically along the machine columns by means of screw/nut screw mechanisms, thus moving the wire up and down.

The wire is rotated by a large diameter driving pulley, which is actuated by belts and inverter controlled asynchronous motor, in order to optimize the wire peripheral speed according to the material to be sawn. Another large diameter driven pulley is constantly kept under tension by a pneumatic cylinder, thus giving the wire the ideal tension. The mechanism is completed by two upper, independent driven pulleys and two pairs of wire-driving pulleys installed next to the point where the wire gets into, and comes out from, the block to be sawn.

Lubrication

A manually operated lubrication system provides lubricant to critical points.

Painting

In order to ensure a high corrosion strength, both the structure and the components are first sand-blasted to prepare the surface before painting, then coated with a zinc-based epoxy primer and lastly with a second bi-components top coat.

Pulley coating

All pulleys are coated with special, interchangeable, wear-resistant elastomer profiles.

Safety measures

A special sensor, connected to the stretching cylinder, detects any possible breakage of the wire and stops the machine instantly.

Automatic adjustment of the wire lowering

When cutting, the wire lowering speed is automatically managed by the machine control sys-tem through sensors, which detect the position of the stretching piston.

Positioning accuracy of the block-holding trolley

The block-holding trolley (on request) has four motorized wheels, which are installed on rugged bearings. Wheels are provided with a special profile acting as a guide along the rails that are fixed to the foundations so as to obtain a perfect parallelism. The system ensures an accurate positioning of the trolley and a precise parallelism of cuts, thus enabling to cut slabs (even thick slabs) with the precision typically required by this type of operation.

Programming

The colour screen and user-friendly software ensure a simple programming, control of the cutting cycle and management of the working axes. A mobile button panel makes the activation of the main working axes easier for the operator.

Device to move the slabs

with vertical motorized positioning, provided with pneumatic cylinder that moves the slabs after they have been cut, thus maintaining the wire deflection set on the prefixed value.

Write to mail@breton.it for an estimate.

I'm done for today.

By-by

Sergio Prior