The Breton Paragon range of multiwire saws for cutting granite blocks has been extended to include a 2100 mm cutting width version that can be configured with up to 78 wires.

NOW AVAILABLE ALSO FOR 5.3mm diamond wire

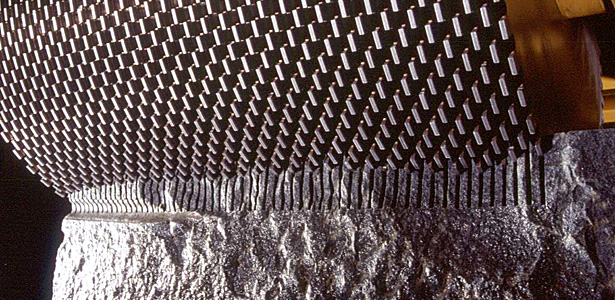

Paragon multi-wire machine with 5.3mm Ø wire

In the picture above, MONDIALGRANIT (counting on 8 operating Breton multi-wire machines) shows its Paragon successfully using the 5,3 mm diamond wire.

INCOMPARABLE AND INNOVATIVE

DRUMS / PULLEYS

WIRE INSTALLATION BY 2 OPERATORS ONLY

WIRE INSTALLATION BY 3 OPERATORS ONLY

If you are considering the purchase of a multi-wire machine for cutting granite blocks and you are interested in receiving an offer on Breton’s “Paragon” write at mail@breton.it.

We will promptly provide you with all necessary information and our offer.

We’ll get back to you promptly.

Bye-bye

Sergio Prior

In order from the smallest machine, the Paragon range also includes the 600, 800, 1000 and 1600 models.

PARAGON

THE NEW BENCHMARK IN THE MARKET

THE NEW BENCHMARK IN THE MARKET

NOW AVAILABLE ALSO FOR 5.3mm diamond wire

Paragon multi-wire machine with 5.3mm Ø wire

In the picture above, MONDIALGRANIT (counting on 8 operating Breton multi-wire machines) shows its Paragon successfully using the 5,3 mm diamond wire.

Breton enriches its product range with Paragon machines, specially conceived to work with 5.3mm wire, for either variable or fixed pitch.

5,3 mm wire potential advantages:

• more slabs from a single block

• less electrical power consumption

• less sludge to be removed

• more slabs from a single block

• less electrical power consumption

• less sludge to be removed

Breton remains

at your disposal to provide you with all necessary information to find

out about cost savings connected to the use of 5.3mm diamond wire.

INCOMPARABLE AND INNOVATIVE

• Triangle geometry with just

five transmissions.

• Diameter of all

transmissions of 1.000mm.

• Adjustable wire driving

drums.

• Easy access to the machine

with practical staircases and gangways.

• Fast and easy wire change

and positioning.

• Immediate and intuitive

touch screen operator interface for machine management.

• Hydraulic tensioner ensuring

a uniform tension among wires.

TRIANGLE CONFIGURATION

DRUMS / PULLEYS

Paragon five rotating drums, all of which have a diameter of 1.000 mm, guarantee minimum wire fatigue and a very low cooling water consumption.

The rigidity of the structure and the isosceles triangular geometry with wires just 20 metres long guarantees lower wire vibrations while cutting, leading to higher cutting quality and longer service life of the rubber profiles.

The rigidity of the structure and the isosceles triangular geometry with wires just 20 metres long guarantees lower wire vibrations while cutting, leading to higher cutting quality and longer service life of the rubber profiles.

THE LOAD-BEARING STRUCTURE

The drums and pulleys are installed inside a rigid, boxed steel structure, which runs along the load-bearing columns, stiffly anchored to the ground and stabilized with steel tie rods that ensure a next-to-nothing deformation for the cutting purpose.

Column deformation while cutting has been checked using finite element mathematical calculations.

Column deformation while cutting has been checked using finite element mathematical calculations.

MAXIMUM ERGONOMICS

WIRE STRETCHING PULLEYS AND WIRE INSTALLATION

Wire stretching pulleys, one for each wire, rotate on bearings and are individually driven by a single hydraulic piston ensuring a uniform and constant tension of each wire; this is essential to prevent wires from being less tensioned, which would reduce the down-feed speed.

Wire stretching pulleys, one for each wire, rotate on bearings and are individually driven by a single hydraulic piston ensuring a uniform and constant tension of each wire; this is essential to prevent wires from being less tensioned, which would reduce the down-feed speed.

The

arc of movement of the wire stretching pulleys is very large, therefore

the wire installation is very easy and any complicated prestretching

system has been eliminated.

The staircase and gangway system allows an easy, quick and safe installation of wires.

The staircase and gangway system allows an easy, quick and safe installation of wires.

WIRE INSTALLATION BY 3 OPERATORS ONLY

OPERATOR INTERFACE

The large colour touch screen makes programming the machine and controlling the processing phases intuitive and user friendly.

All the work settings and parameters can be controlled and displayed on simple pages with big, clearly visible characters.

The “statistics” section lets you display and extract all the data required to manage sawmill and diamond wires, which feature a wisely structured architecture whether you saw blocks for your own company or for third parties.

The large colour touch screen makes programming the machine and controlling the processing phases intuitive and user friendly.

All the work settings and parameters can be controlled and displayed on simple pages with big, clearly visible characters.

The “statistics” section lets you display and extract all the data required to manage sawmill and diamond wires, which feature a wisely structured architecture whether you saw blocks for your own company or for third parties.

Machine height with wires positioned at the end of cutting 620cm

Machine height 730-790cm.

If you are considering the purchase of a multi-wire machine for cutting granite blocks and you are interested in receiving an offer on Breton’s “Paragon” write at mail@breton.it.

We will promptly provide you with all necessary information and our offer.

We’ll get back to you promptly.

Bye-bye

Sergio Prior